Galvanic corrosion is a severe issue in aerospace engineering, affecting the durability and integrity of aircraft structures. It occurs when two dissimilar metals come into electrical contact in the presence of an electrolyte, such as moisture, leading to accelerated corrosion that weakens components and structures.

This phenomenon is particularly concerning in aircraft due to their exposure to various environmental conditions, including high humidity, salt-laden air and temperature fluctuations. To maximise the lifespan of components and ensure the safety of designs, engineers need to have a clear understanding of how to detect and prevent galvanic corrosion.

The risks of galvanic corrosion when it comes to aircraft

Galvanic corrosion can compromise the structural integrity of aircraft components, leading to potential failure, increased costs over time and other detrimental factors.

- Structural weakness: Corrosion compromises the mechanical integrity of components, increasing the risk of failure.

- Increased maintenance costs: Frequent inspections and replacements of corroded parts drive up operational expenses.

- Reduced aircraft lifespan: Long-term exposure to galvanic corrosion significantly shortens the service life of aircraft components.

- Safety hazards: Corroded fasteners and structural elements can lead to catastrophic failures if not addressed in time.

⚙️ Aircraft corrosion: Causes and engineering solutions – Learn more

Ways to detect galvanic corrosion in aircraft

Early detection is crucial in mitigating the effects of galvanic corrosion. Fortunately, there are a number of inspection methods available for engineers to catch corrosion early.

- Visual inspection: Signs of corrosion include discoloration, pitting, and material loss at metal junctions.

- Non-Destructive Testing (NDT):

- Ultrasonic Testing (UT) detects subsurface damage.

- Eddy Current Testing (ECT) identifies corrosion in conductive materials.

- Radiographic Inspection (X-ray) reveals hidden corrosion.

- Electrochemical analysis: Measures the potential difference between metals to assess the likelihood of corrosion.

- Environmental monitoring: Sensors detect moisture levels and atmospheric conditions that accelerate corrosion.

The importance of galvanic corrosion prevention

Preventing galvanic corrosion goes beyond extending the lifespan of aircraft components to ensure flight safety and reducing operational costs. Once corrosion sets in, it can spread rapidly, weakening critical structures and leading to costly repairs or replacements. Implementing proactive prevention methods is far more effective than addressing galvanic corrosion damage after it occurs, making it a top priority in aerospace engineering.

Material selection

Choosing materials with similar electrochemical properties is the most effective way to prevent galvanic corrosion. When possible, engineers opt for materials that minimise the potential difference between contact metals. In cases where dissimilar metals must be used, additional protective measures are required.

Protective coatings and surface treatments

Applying protective coatings and surface treatments can create a barrier between metals and the surrounding environment.

- Anodising: Forms an oxide layer on aluminium, enhancing its resistance to corrosion.

- Cadmium and zinc plating: Provides sacrificial protection for aluminium and steel components.

- Sealants and specialised paints: Act as insulating layers to prevent direct metal-to-metal contact.

✈️ Aircraft corrosion prevention: Best practices for aerospace engineers – Learn more

Why wire thread inserts are the best solution for galvanic corrosion prevention

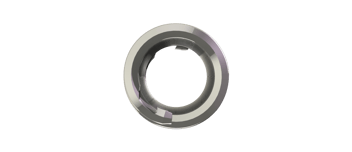

Wire thread inserts provide a robust solution for mitigating galvanic corrosion in aircraft mechanical joints. These inserts are installed into tapped holes, creating a durable, corrosion-resistant interface between fasteners and the parent material.

By isolating the fastener from the parent metal, wire thread inserts effectively break the electrochemical circuit that causes galvanic corrosion. Their ability to distribute load evenly also minimises localised stress, which can contribute to corrosion initiation.

Wire thread inserts are available in corrosion-resistant materials such as phosphor bronze, stainless steel, and Inconel-X750. They can also be coated with protective finishes like cadmium or silver plating to further enhance resistance to harsh environments.

Additional benefits of wire thread inserts

Beyond galvanic corrosion prevention, wire thread inserts also provide a number of additional benefits to aircraft designs.

- Enhanced joint strength: Prevents thread stripping and joint failures.

- Simplified maintenance: Allows easy removal and replacement of fasteners without damaging the parent material.

- Extended component life: Reduces the need for frequent replacements, cutting maintenance costs and improving aircraft reliability.

Industry leading protection for aircraft and mechanical joints

Galvanic corrosion remains a major threat to aircraft integrity, impacting structural stability, maintenance costs, and overall safety. Preventative measures such as material selection, protective coatings, insulation, and environmental control play a critical role in mitigating its effects. However, one of the most effective solutions for combating galvanic corrosion in mechanical joints is the use of wire thread inserts.

KATO Advanex wire thread inserts offer unmatched reliability in aerospace applications. Designed to prevent direct metal-to-metal contact, they serve as an insulating barrier, reducing the risk of galvanic corrosion while enhancing fastener strength and durability. Available in various corrosion-resistant materials and specialised coatings, KATO Advanex inserts provide superior performance in extreme environments, ensuring long-term joint integrity and reduced maintenance requirements.

For engineers looking to improve the resilience of aircraft components, integrating wire thread inserts is a smart and cost-effective choice. To learn more about how KATO Advanex wire thread inserts can enhance your aerospace designs, download our comprehensive guide on wire thread inserts below.

.jpg?width=352&name=automotive%20fastener%20(1).jpg)