Enhancing the durability and lifespan of components is a widespread challenge across engineering industries. Fastening elements play an important role in this durability, as a lack of strength and reliability in joints usually makes them the first point of failure.

Helicoil inserts are a solution to both enhancing the strength of joints and providing excellent durability. In this article, we unpack what helicoil inserts are, how they function as a superior fastening solution and the benefits they bring to engineers and manufacturers.

What are helicoil inserts?

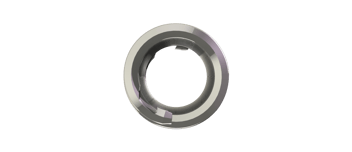

The namesake of helicoil inserts comes from their design. They consist of diamond-shaped wire that is helically-coiled to create a threaded insert. This insert is then used as a fastening solution that fits between a bolt/screw and the parent material of a stamped hole. Helicoil inserts enhance the strength, durability and lifespan of joints by dispersing the contact stress between bolts/screws and the parent material.

How are helicoil inserts installed?

When installed, the coil becomes compressed and “locks” the helicoil insert into place. This creates an equal dispersion of contact, as the coil adjusts radially and axially across the bolt/screw. This provides significantly superior fastening properties when compared to standard fastening with bolts/screws and threaded holes.

The installation of tanged and tangless helicoil inserts differ slightly. With tanged, an installation tool grips the tang, which then breaks off when reaching an optimal position. For tangless, a specialised tool is used that grips an internal notch; this means that tangless helicoil inserts can be easily removed, whereas tanged inserts cannot.

What do helicoil inserts provide?

Helicoil inserts provide a range of beneficial features for components as a superior fastening solution:

- Strength - Helicoil inserts distribute contact evenly across the length of the screw and bolt. This enhances the strength of the fastening by reducing stress and fatigue concentrations and maximising potential contact.

- Protection - The dispersed contact of helicoil inserts provides protection from wear, stripping and seizing. They also provide additional protection from factors such as vibrations and corrosion, leading to durable and reliable joints.

- Integration - Helicoil inserts are able to protect lighter and softer materials from wear that would otherwise happen without their integration. This enables the integration and use of lighter metals to optimise designs.

Why do manufacturers use helicoil inserts?

The superior features of helicoil inserts bring a range of benefits for manufacturers and engineers:

- Component lifespan and durability - The resilient characteristics of helicoil inserts are translated into the components they are used in. The joints are strengthened and protected from factors that can damage lifespan, leading to longer lasting and durable components.

- Cost and time effective solution - The installation of any type of helicoil insert is quick and cost effective. This enables manufacturers to bring large-scale optimisations to components without a significant loss to resources.

- Reliability and safety - For applications such as aerospace where safety is a priority, helicoil inserts provide reliability in the strength and durability of joints. They also come in a variety of material compositions and surface finishes to provide additional protection in certain applications.

KATO® Advanex: industry leading helicoil inserts

Helicoil inserts provide significant value to manufacturers and engineers. They strengthen joints through their simple yet innovative design without compromising on time and cost of manufacture. All in all, they bring a number of benefits with no downsides.

KATO® Advanex are industry leaders in wire thread and helicoil inserts, providing tanged and the innovative tangless solutions. Our products are widespread in the aerospace, automotive, electronics and railway industries thanks to their consistent, reliable and protective designs.

To find out more about KATO® Advanex and our wire thread and helicoil inserts, contact a member of our team today.

.jpg?width=352&name=Shutterstock_37577614%20(1).jpg)