Helically coiled thread inserts are a key component in enhancing the performance and durability of repairable threaded mechanical joints. One of their key features is the significant enhancement to joint and shear strength once installed, which is thanks to a number of innovative design features.

In this article, we delve into the properties that provide the joint strength in which helically coiled thread inserts are known and widely used for.

What are helically coiled thread inserts?

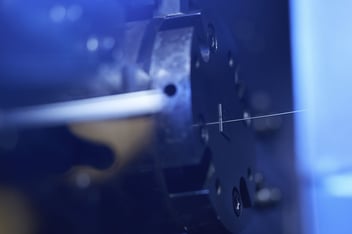

Helically coiled thread inserts, sometimes referred to as helicoils or wire thread inserts, are precisely engineered to enhance the strength and durability of threaded joints. These inserts are made from high-strength, coiled wire featuring a diamond-shaped cross-section that forms a helix. This design allows the insert to be threaded into a matching tapped hole within a host material. Once installed, it provides a durable, threaded interface that is stronger than the original threads in the host material. Helically coiled thread inserts are particularly useful in materials that are relatively soft or brittle, where thread wear, stripping or damage is a concern, such as aluminium alloys.

The design features that make helically coiled thread inserts invaluable

Retention principle

The fundamental advantage of helically coiled thread inserts lies in their retention principle. Once installed, these inserts create a wear-resistant thread in the host material that can significantly outperform traditional threads. The retention is achieved through the radial pressure exerted by the insert against the walls of the host material, securing the insert in place. This mechanism not only provides a high resistance to vibration and torsional stresses but also ensures the integrity of the joint over the lifecycle of the assembly.

Elasticity and diamond-shaped coil

One of the standout features of helically coiled thread inserts is their inherent elasticity, afforded by the unique diamond-shaped design of the coil. This structure allows the insert to expand elastically, which accommodates manufacturing tolerances and thermal expansion variations between the insert and the host material. This elasticity aids in the installation process of the insert and helps distribute loads evenly, reducing peak stress points that can lead to thread wear.

Low-thread friction torque

Helically coiled thread inserts are designed to reduce friction during both the installation of the bolt and during its operational lifetime. The low-thread friction torque ensures smoother assembly and disassembly processes, which is critical in applications requiring frequent maintenance. This feature directly contributes to the longevity of both the insert and the host material, preserving the integrity of the threads under dynamic loads and reducing the risk of galling or seizing.

Strong locking capacity

The locking capacity of helically coiled thread inserts is enhanced by their full 360-degree contact with the bolt or screw. This complete engagement maximises load distribution across all threads, significantly increasing the load-bearing capacity of the joint. The insert’s design effectively mitigates common issues such as pull-out, stripping and torque-induced loosening, making it an ideal choice for applications subjected to high dynamic loads.

Integrate leading helically coiled thread inserts with KATO® Advanex

Helically coiled thread inserts represent a significant advancement in fastening technology, addressing several challenges faced in modern engineering joints. Their strong design features enhance the mechanical properties of assemblies and help contribute to more sustainable and cost-effective manufacturing practices. By enabling the use of lighter and softer materials without compromising on performance, these inserts play a crucial role in the advancement of engineering designs, particularly in industries like aerospace, automotive, and electronics where reliability and performance are non-negotiable.

At KATO® Advanex, we are leading manufacturers of high-quality helically coiled thread inserts that are available in both Tanged and Tangless® designs. Across every industry, our inserts form strong, resilient and lightweight joints that reduce costs, improve fuel economy and inspire innovation. Our helically coiled thread inserts are available in a wide range of material compositions, surface finishes and design specifications to make it simple to find the perfect joint solution for your design.

To find out more about our products or to get additional pricing information, contact a member of our team today.

.jpg?width=352&name=Shutterstock_2288877403%20(1).jpg)