Tanged wire thread inserts have been a staple of many industries for decades, helping to strengthen joints and make them more durable. However, their exposed tang can bring a number of new challenges such as foreign object debris and difficulty in performing maintenance.

Tang-free wire thread inserts bring an alternative fastening solution that eliminates the challenges tied to their predecessor’s exposed tang. In this article, we unpack tang-free wire thread inserts, their features and the benefits they bring to manufacturers.

What are tang-free wire thread inserts?

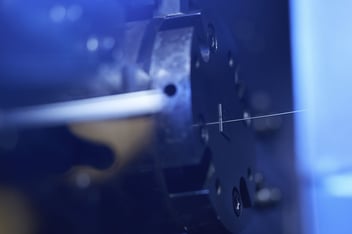

Tang-free wire thread inserts are alternatives to their traditionally tanged counterparts. Their namesake comes from the lack of exposed tang at the top of their design. Conventionally, this tang is used to grip the insert and break off when reaching optimal placement.

With tang-free wire thread inserts, the tang is replaced by an internal notch on the helical coil that is gripped by a specialised tool during installation. This eliminates the need for a tang that breaks off, bringing a range of beneficial features to applications.

What are the features of tang-free wire thread inserts?

Free of FOD

Foreign object debris (FOD) is an inevitable part of using tanged inserts. The broken off tang needs to be retrieved after installation, or can pose significant dangers for industries such as aviation. Because of this, tang retrieval is a necessary process that needs to be performed after wire thread insert installation.

Tang-free wire thread inserts effectively eliminate the need for tang retrieval. Their internal notch design replaces it entirely and only requires specialised tooling that can grip the notch for installation.

Bi-directional design

Tanged wire thread inserts are unidirectional, meaning that they are designed to be installed rather than removed. For maintenance or component replacement, this can cause complications where it can be difficult and time consuming to remove them from threaded holes without causing damage.

Tang-free wire thread inserts showcase a bidirectional design, meaning they can be easily installed and removed. Moreover, they can be installed/removed quicker than their tanged counterparts without the risk of damage to the parent material.

Equal strength

The tang on conventional wire thread inserts break off once the insert has reached optimal tension radially and axially within the parent material. This ensures optimal strength as a fastening solution with equal dissipation of contact strength across the insert.

As tang-free wire thread inserts do not have a tang that breaks off, it can be reasonable to assume they do not share the same level of strength. However, specialised tooling replaces the need for a tang to ensure optimal thread placement so there is no loss to strength whatsoever.

What are the benefits of tang-free wire thread inserts?

Faster installation and removal

As tang-free wire thread inserts are bidirectional, it makes the installation and removal of them quick and easy. This can optimise the speed of manufacturing by up to 10x of that of tanged wire thread inserts depending on the tooling used; this has a knock on effect of speeding up the whole manufacturing cycle in a number of industries.

Making maintenance simple

Tang-free wire thread inserts are designed to be easily removed. This makes the maintenance of components, threaded holes or even the inserts themselves a simple and time effective process. As a result, the downtime of components is reduced significantly, getting products back into the field ASAP.

No need for FOD retrieval

The necessary step of retrieving tangs to avoid FOD can be entirely skipped with the use of tang-free wire thread inserts. This saves significant time and costs depending on the industry. For example, the usage of millimetre wave radio to detect FOD in aviation is not needed for component manufacturing, saving a bit of the billions in damage and maintenance costs attributed to it each year.

KATO® Advanex - Industry leading tang-free wire thread inserts

Tang-free wire thread inserts pose an innovative solution to the handful of challenges brought by the use of their tanged alternatives. They eliminate the risk of FOD, exhibit a time-effective bidirectional design and exhibit an equal level of strength and durability.

At KATO® Advanex, we are innovators in the field of tang-free wire thread inserts. We have 25 years of experience in strengthening joints and providing bespoke solutions through a selection of sizes, coatings and materials. We directly help optimise designs in automotive, aerospace, automotive and many other industries.

To find out more about KATO® Advanex’s tang-free wire thread inserts and how they can optimise your design, contact a member of our team today.

.jpg?width=352&name=Weighing%20medical%20components%202%20(1).jpg)

.jpg?width=352&name=KATO%20PLANE%20(1).jpg)