Mechanical joints are critical in engineering, serving as vital connections within structures and machinery. However, they often face challenges such as fretting fatigue, corrosion and wear which can compromise performance and longevity.

Wire thread inserts are a valuable solution that improves joint performance, lifespan and durability. They provide protection against corrosion and wear, while also streamlining installation and maintenance processes.

In this article, we'll explore the benefits of wire thread inserts and how they can significantly enhance the performance and lifespan of mechanical joints.

Prolong - long-term durability for designs

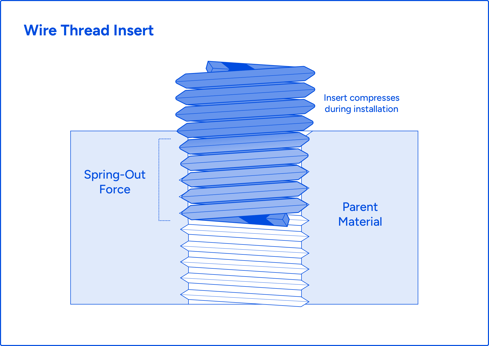

Wire thread inserts are a simple-to-install joining element that enhance the overall performance, strength and lifespan of mechanical joints. This is thanks to the insert adjusting radially and axially between a bolt and threaded hole of a joint when installed, securing the maximum surface contact between the parent materials. As a result, shear strength of the joint is maximised by dissipating the contact force between the bolt and parent material.

As loads are distributed evenly across each thread, wire thread inserts also prolong the lifespan of mechanical joints. Stress and fatigue concentrations are commonplace with bolt and screw joints, making the use of lightweight and soft metals difficult due to wear. But wire thread inserts minimise fatigue, enabling lightweighting while prolonging the lifespan of mechanical joints.

Protection - resistance to environmental and application factors

Wire thread inserts function as a protective layer between the tapped holes and threaded bolts of mechanical joints. Moreover, the material composition and surface finish of the insert can be chose to enhance its protective and resistant features in any given application.

Corrosion

Galvanic corrosion is a prevalent issue for mechanical joints, especially when using dissimilar and lightweight materials. Wire thread inserts act as a protective barrier to prevent galvanic corrosion from taking place. They can also be made from phosphor bronze to provide additional corrosion resistance in particularly harsh environments such as those with high concentrations of salt water.

Wear

Fretting and thread wear are also common issues for mechanical joints when using softer and lighter materials. This is a result of stress concentrations at different points of the bolt within a tapped hole. Wire thread inserts resolve this issue by dissipating tension across the length of the bolt. Not only does this reduce wear, but it also maximises the joint’s shear strength. Wire thread inserts consisting of Nitronic 60 can also be used to further enhance a joint’s resistance to wear, fretting and galling.

Thermal

For specific applications or components, mechanical joints need to showcase resistance to high temperatures. Whether it’s internal engine components for automotive or aerospace designs, these joints need to maintain tensile strength at considerably high temperatures without any risk of deformation. Wire thread inserts made from Inconel-X750 can provide these features at temperatures up to 1,000° F, all the while providing other benefits such as enhanced joint strength.

Manufacturability - fast installation/maintenance at low cost

An inadvertent factor of performance with mechanical joints is productivity through installation and maintenance. A key use case of wire thread inserts is as a repair and maintenance tool for existing mechanical joints. If tapped holes have lost their threading or simply lack the required shear strength, wire thread inserts can be installed to enhance their strength and provide additional protection to external factors.

In this respect, wire thread inserts are immensely efficient in both their installation and removal. With the right tooling, a hole can be rethreaded with an insert installed in minutes. This greatly enhances productivity and minimises time that would otherwise be spent performing meticulous maintenance. And for joints that already have wire thread inserts and require maintenance, these can be removed and replaced in seconds.

Enhance the performance of your mechanical joint with KATO® Advanex

Wire thread inserts bring a range of benefits to mechanical joints. They improve their performance and lifespan, provide protection against environmental and application factors and simplify the maintenance process.

At KATO® Advanex, we provide an extensive range of high-performance wire thread inserts in a number of material compositions and surface finishes. We also offer the traditional Tanged wire thread insert as well as our own Tangless® design that minimises debris and maximises productivity.

Our team of specialists can help you find the perfect wire thread insert for your design to take advantage of all the benefits for your mechanical joint. To find out more about our products or to get additional pricing information, contact a member of our team today.

.jpg?width=352&name=KATO%20PLANE%20(2).jpg)

.jpg?width=352&name=Shutterstock_2096504170%20(1).jpg)