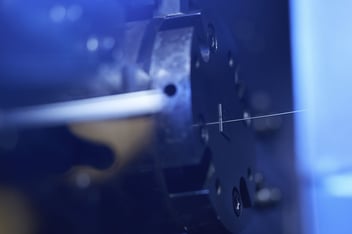

Coil thread inserts enable the integration of lighter and softer metals into components that face wear, corrosion and other factors. This results in improved fuel efficiency and reduced costs for engineering designs.

There are a number of different coil thread solutions that each provide specific resistances, shear strength and suit various sizes/lengths. It is vital that you understand the importance of coil thread inserts in relation to your application to arrive at the perfect type for your design.

In this guide, we explore the specific variables that affect coil thread choice and how you can choose the perfect one for your design.

Understanding the variables when it comes to coil thread inserts

The first step in finding the perfect coil thread for your design is to have a complete understanding of your application requirements. This means carefully looking at each aspect that influences the performance, durability and selection of different coil thread types.

Start with the application

The specific application can have a major impact on the choice of coil thread insert. For example, aerospace designs require significant corrosion resistance and durability to perform in external mechanical joints. On the other hand, internal engine components in automotive designs need to perform reliably across a range of operating temperatures. Simply put, you need to have a clear understanding of what your application needs and what it is facing.

Then dive into the specific variables

- Parent material - The hardness and durability of the parent material plays an important role in the choice of coil thread insert. If one material is softer than the other, the more important it is to find a coil thread that fits and dissipates load as evenly as possible.

- Conditions - You need a clear understanding of the conditions faced by the joint, parent material and application as a whole. Whether it’s corrosion, thermal or wear, you need to know what you need resistance from.

- Standards - Depending on your specific application you’ll need to comply with a number of standards. This includes coil thread inserts that need to be compliant with military, aerospace and commercial standards. You just need to know which one applies to your design.

Understanding different coil thread types to suit your specific design

Once you have a clear understanding of your needs when it comes to joints, you then need to look at the different types of available coil thread inserts. These come in a range of types, material compositions, finishes and lengths. The key is to know the specifics of each so you can arrive at an optimal joint solution that provides the features your design needs.

Tanged or tangless

Tanged coil thread inserts follow the traditional design of a tang that breaks off once optimal installation has been achieved. This is a clear and simple way of ensuring your joints have optimal shear strength, but requires a tang retrieval process to remove FOD (foreign object debris) that can lead to potential problems down the line.

Tangless coil thread inserts eliminate the tang retrieval process by, as their name suggests, removing the tang. With a unique bi-directional notch design and specialised tooling, you can install and remove tangless coil threads quickly, easily and without the need of FOD retrieval. As a result, you can speed up the design cycle as well as maintenance with their simple removal process.

Material composition

After establishing the conditions your applications will face, the next step is to decide upon a specific material composition. These are what provide coil thread inserts with specific resistances to enhance your joint performance and guarantee long-term functionality.

- 304 stainless steel - The most common material composition that acts as a baseline for strength, corrosion resistance and temperature capability. Provides decent protection for each but not suitable for extreme conditions.

- Phosphor bronze - Enhanced corrosion resistance. Suitable for salt water and high corrosive applications to maintain strength over extended periods.

- Inconel-X750 - Designed for high temperature environments. Can maintain strength and withstand deformation at temperatures up to 1,000° F.

- Nitronic 60 - Provides enhanced resistance to wear, fretting and galling, as well as raised thermal resistance. Suitable for applications with softer parent materials.

Surface finish

Following material composition is the surface finish of coil thread inserts. These provide additional protective features to suit applications that face a number of harsh conditions. By combining compositions and finishes of coil thread inserts, you can be confident in the performance and long-term reliability of your joints.

- Cadmium - Provides additional corrosive protection as well as resistance to galling by reducing the coefficient of friction between the insert and bolt.

- Silver - Provides lubricity at high temperatures to maintain performance for internal components.

- Colour Identifier - Coloured inserts using Ink to be used as an identifier. Benefits specific applications and makes maintenance easier.

Size (length and drill size)

Distinguishing the right size and length for your coil thread insert is vital to balance the bolt tensile strength against the shear strength of the parent material. The bolt must engage the entire length of the insert to achieve maximum assembly strength. This is especially important for softer parent materials, as any concentration of tension can lead to different forms of wear.

There are five nominal lengths for coil thread inserts, with examples below of appropriate lengths and size for different tensile strengths.

.png?width=512&height=208&name=unnamed%20(14).png) Match your design needs to the right coil thread insert features

Match your design needs to the right coil thread insert features

With an understanding of both your application variables and different coil thread insert features, you have the knowledge to choose the perfect solution for your design. By selecting the right type, material composition, surface finish and size/length, you can integrate specific components (lightweight, soft parent materials, etc.) and enhance your designs.

Integrate the perfect coil thread insert that is fully compliant with KATO® Advanex

It can be daunting to try and work out the specific variables involved with coil thread inserts. But with an understanding of your application and the features of said inserts, you can easily arrive at the perfect solution.

At KATO® Advanex, we provide an extensive range of Tanged and Tangless coil thread inserts in multiple compositions, finishes and sizes. Each of our inserts and tools are in full conformance with military, aerospace, and commercial standards and specifications. All you need to do is find the right one for you, which our team of specialists can help you with.

To find out more about our products or to get additional pricing information, contact a member of our team today.

.jpg?width=352&name=Shutterstock_2382368291%20(1).jpg)

.jpg?width=352&name=Shutterstock_1375070846%20(1).jpg)