Mechanical joints are a fundamental part of engineering and design, forming the backbone of structures and assemblies across industries. From aerospace to automotive and construction, the choice of a suitable joint type is a critical decision that directly impacts performance and reliability.

There are two primary categories of mechanical joints that suit different design needs - permanent and temporary. In order to choose the best fit for a specific design, engineers need to have a clear understanding of both types, including their applications, strengths and considerations for selecting the right one.

What are permanent mechanical joints?

Permanent joints are designed to create a lasting connection between components. Once assembled, these joints are not meant to be disassembled without causing damage to the components or the joint itself.

Common types of permanent joints

- Welding: Involves fusing materials using heat or pressure. Welding provides high strength and durability, making it ideal for structural applications.

- Applications: Steel frameworks, pipelines, and automotive bodies.

- Brazing and soldering: Use a filler material to bond two components without melting the base materials. Offers compatibility with delicate components and minimises thermal distortion, ideal for precision work.

- Applications: Electronics, HVAC systems, and delicate assemblies.

- Riveting: Mechanical fasteners that permanently secure materials by deforming their ends. Rivets are widely used where welding isn’t feasible.

- Applications: Aircraft skin panels, bridges, and boilers.

Advantages

- High strength and durability.

- Resistance to vibration, corrosion and wear.

- Seamless and leak-proof connections.

Disadvantages

- Inflexibility where disassembly results in component damage.

- Time-consuming and labor-intensive to create.

- Limited reusability leads to poor sustainability.

What are temporary mechanical joints

Temporary joints are designed for disassembly and reassembly without damaging the components. These are ideal for applications requiring maintenance, repair or adjustments over time.

Types of temporary joint

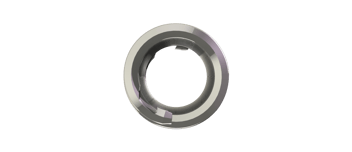

- Press fits: Rely on interference between mating parts to create a secure joint. While removable, they may require specialised tools for disassembly.

- Applications: Bearings, shafts and gear assemblies.

- Fasteners: Bolts, screws and nuts are the most common types of fasteners. They create secure joints by applying clamping forces but allow easy disassembly. Additional solutions like wire thread inserts can further enhance the strength and durability of these joints by sitting between the bolt and parent material.

- Applications: Machinery, automotive engines and consumer electronics. With wire thread inserts, this can extend to areas like aerospace designs, lightweight automotive components and electronics enclosures.

- Clamp joints: Clamp joints rely on external clamping forces, often using brackets or clips, to hold components together. They are non-invasive, easily adjustable, and ideal for applications requiring quick assembly and disassembly.

- Applications: Bearings, gear assemblies, and automotive engines.

Advantages

- Easy disassembly and maintenance.

- Cost-effective for applications requiring frequent adjustments.

- Compatibility with lightweight and soft materials using wire thread inserts.

- Reusable to enhance sustainability and bring flexibility to designs

Disadvantages

- Potentially lower strength compared to permanent joints.

- Prone to loosening under vibrations unless secured properly (e.g., using thread-locking solutions or wire thread inserts).

- May require regular maintenance to ensure performance, but maintenance is far easier.

Permanent and temporary joints compared

|

Feature |

Permanent Joints |

Temporary Joints |

|

Disassembly |

Not possible without damage |

Easily disassembled and reassembled |

|

Strength |

Generally higher |

Lower but sufficient for most applications |

|

Applications |

Structural and long-term installations |

Maintenance-heavy or adjustable setups |

|

Maintenance |

Minimal maintenance required |

Requires periodic checks and adjustments |

|

Cost |

Higher upfront cost |

Lower initial cost, but potential ongoing expenses |

Which type of mechanical joint is better?

The choice between permanent and temporary joints depends largely on the application’s requirements. Permanent joints are ideal when strength and durability are critical, such as in structural frameworks or high-stress environments. They also excel in leak-proof applications like pipelines and in scenarios where maintenance is impractical, such as underwater or aerospace projects.

Temporary joints, however, are more suitable for applications prioritising maintenance and flexibility. These joints are invaluable in machinery and systems requiring frequent adjustments or disassembly. Techniques like clamp joints are especially effective for lightweight materials, offering secure fastening without compromising structural integrity. Additionally, temporary joints provide unmatched adaptability for designs that demand regular reconfiguration or upgrades.

Fasteners and wire thread inserts play a critical role in temporary joints, offering lightweighting advantages and boosting fuel efficiency in industries like aerospace and automotive. Fasteners enable secure yet removable connections, essential for systems requiring regular maintenance or reconfiguration. Wire thread inserts further enhance performance by providing strong, durable threading for lightweight materials like aluminium, preventing wear and increasing joint reliability.

Elevate your design through innovative joining solutions

Mechanical joints, whether permanent or temporary, are indispensable to engineering and manufacturing. Permanent joints offer unrivalled strength and longevity, making them ideal for structural and high-stress applications. Temporary joints, on the other hand, excel in flexibility and maintenance ease, particularly when paired with innovative solutions like wire thread inserts.

Wire thread inserts are an indispensable component for creating strong, lightweight, and reliable joints, especially in industries like aerospace and automotive. Their ability to reinforce soft materials like aluminium, distribute stress evenly, and resist wear makes them critical for optimising designs focused on fuel efficiency and performance. To explore their full potential and how they can elevate your projects, read our comprehensive guide on wire thread inserts below.