Vibration resistance in wire thread inserts

Vibrations gradually degrade joint integrity regardless of the specific industry, and can lead to loosening and fatigue of..

Vibrations gradually degrade joint integrity regardless of the specific industry, and can lead to loosening and fatigue of..

We explore the integration of wire thread inserts into 3D printed parts, examining their benefits and potential challenges..

The ability of a threaded insert to resist pull-out or stripping is critical to ensuring safety and reliability, and wire..

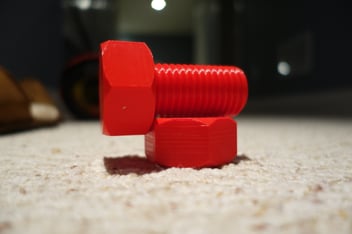

.jpg?width=352&name=automotive%20fastener%20(1).jpg)

In order to choose the best fit for a specific design, engineers need to have a clear understanding of both types

Let’s explore and compare the failure load and fatigue life of various wire thread insert types.

As a leader in fastening technology, KATO® Advanex delivers a suite of wire thread inserts that excel in high-performance..

In order to figure out the best fit for their designs, engineers need an understanding of the key scenarios where..

In order to combat fretting corrosion, engineers need a clear understanding of what it is, why it happens and what can be..

Understanding what causes pitting corrosion, how to detect it and the most effective methods of remediation is critical for..

.jpg?width=352&name=aircraft%20maintenance%20(1).jpg)

We explore what exfoliation corrosion is, why it poses a specific risk to aircraft and how engineers can address it.

Understanding how to identify and mitigate surface corrosion is essential for ensuring aircraft reliability and safety.

To maximise the lifespan of components and ensure the safety of designs, engineers need to have a clear understanding of how..